[youtube:http://youtube.com/watch?v=5k4R5u-oOu0]

Mobile Paintless Dent Removal (PDR) and minor dent repair is reaching new heights!

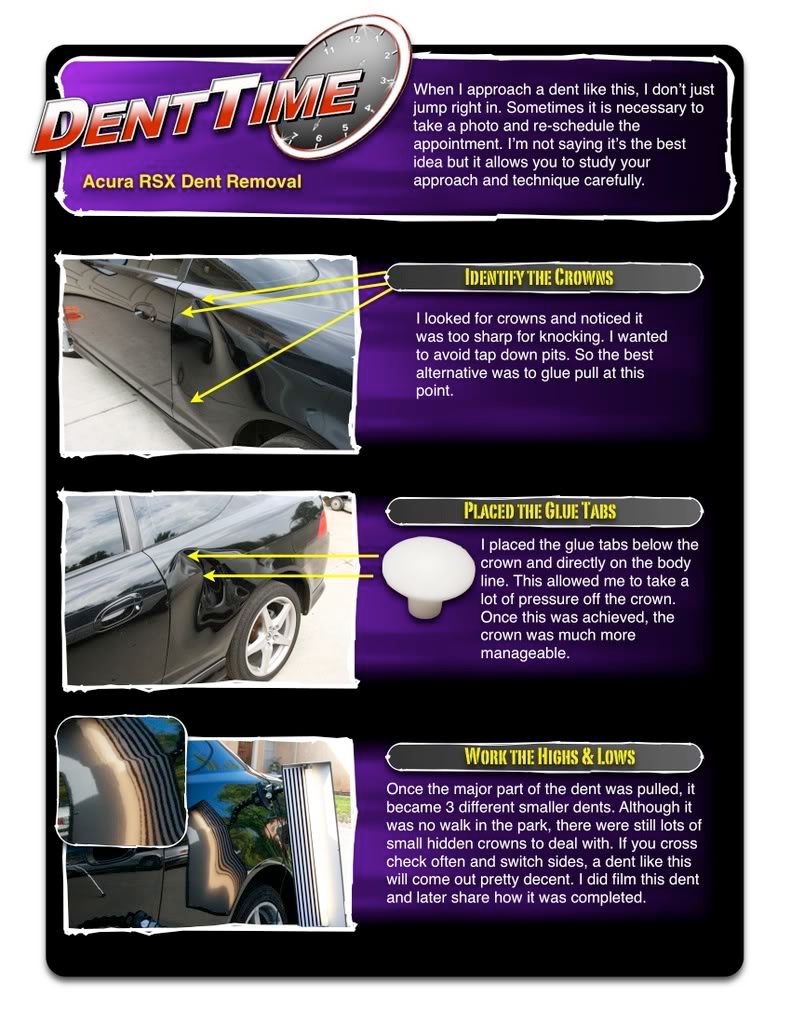

For some time now, PDR has been pushing the envelope on just how big and complex a dent can be fixed. PDR is reaching new heights and becoming such a respected craft major insurance companies are considering PDR a first choice if the paint has not been damaged. Here below you will witness a quite large and complex dent repair performed by Dent Time

The limits of paintless dent removal are being “pushed” literally and physically! In fact there actually might be a new nick name, (PCR). Which stands for “Paintless Collision Repair.” We’re joking a little though. The limits of PDR are endless as long as the paint has not been damaged. Although, not any ordinary PDR tech can achieve dents like you just saw. It takes determination, patience and skill to gain successful and consistent results for such complex dents.

Advanced PDR Training is recommended to gain new techniques to speed up one’s learning curve instead of the old trial and error.

Please visit ReconExpress.com for more info or find a local technician in your area.